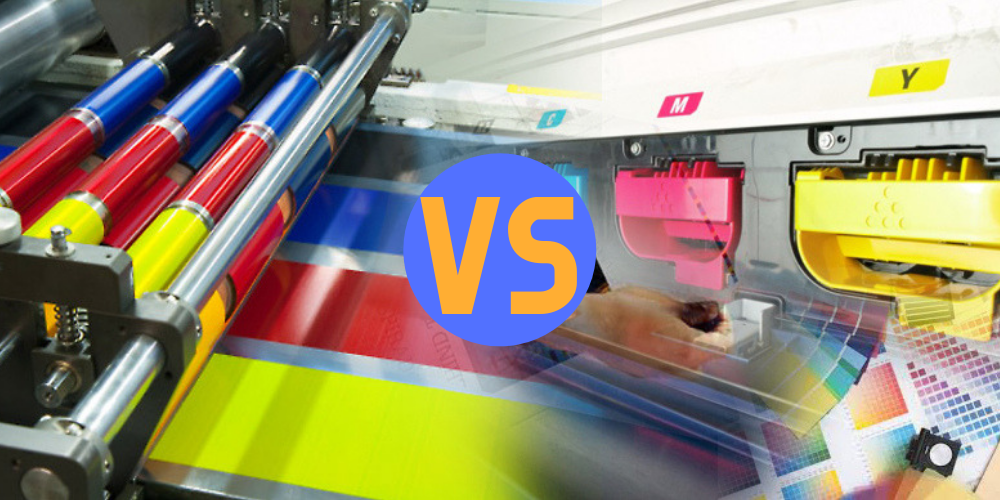

Digital Printing vs Offset Printing: How To You Choose The Best Option For Your Print Project

You have been working hard on new marketing materials for your business and the time has come… you are ready to send them out to get printed! Congrats! However, now you are feeling a bit overwhelmed! You have to decide between two printing methods: Offset Printing and Digital Printingand you have no idea what the difference is or which to choose!

Have no fear! We are here to help! Deciding on whether to use digital or offset printing really just depends on your project. Today, we are going to help you understand each method, the advantages, and disadvantages of each, as well as go over a few factors you need to consider before you choose to have your prints run digitally or offset.

Understanding the Difference

While both printing methods are very popular, there are distinct differences between the two. Understanding these differences will help you easily determine which is a better fit for your specific project.

Offset Printing

Offset Printing, also referred to as lithography, is a common printing technique in which the image, text, artwork, etc. are burned onto a plate and is then transferred (or offset) from the plate to a rubber blanket, and then to the printing surface. The lithographic process is based on the repulsion of oil and water. The image to be printed gets ink from ink rollers, while the non-printing area attracts a film of water, keeping the non-printing areas ink-free. This method is best for large runs and provides accurate color reproduction resulting in a clean and professional product.

Offset Printing, also referred to as lithography, is a common printing technique in which the image, text, artwork, etc. are burned onto a plate and is then transferred (or offset) from the plate to a rubber blanket, and then to the printing surface. The lithographic process is based on the repulsion of oil and water. The image to be printed gets ink from ink rollers, while the non-printing area attracts a film of water, keeping the non-printing areas ink-free. This method is best for large runs and provides accurate color reproduction resulting in a clean and professional product.

Advantages of Offset Printing

- High image quality.

- Works on a wide range of printing surfaces including paper, wood, cloth, metal, leather, rough paper and plastic.

- Quality and cost-effectiveness in high volume jobs.

- Great for large format projects

- Specialized Colors & Techniques – Offset presses can print PMS colors and utilize gloss/dull varnishes for added texture. Additionally, multiple press “heads” allow for an infinite array of colors and printing techniques.

Digital Printing

Digital printing is the computerized reproduction method in which your chosen electronic file is printed directly to the printing surface by the machine. The printing process uses toner in a combined mix of Cyan, Magenta, Yellow, and Black dots to create the image. Digital printing eliminates many of the mechanical steps required for conventional printing, including making films and color proofs, manually stripping the pieces together and making plates.This method is typically used on short-run jobs using a large format or high volume laser or inkjet printer.

Digital printing is the computerized reproduction method in which your chosen electronic file is printed directly to the printing surface by the machine. The printing process uses toner in a combined mix of Cyan, Magenta, Yellow, and Black dots to create the image. Digital printing eliminates many of the mechanical steps required for conventional printing, including making films and color proofs, manually stripping the pieces together and making plates.This method is typically used on short-run jobs using a large format or high volume laser or inkjet printer.

Advantages of Digital Printing

- Shorter turnaround and faster setup.

- Every print is the same. More accurate counts, less waste and fewer variations, due to not having to balance ink and water during the press run.

- Cheaper low volume printing. Digital printing provides lower per-unit costs for very small print runs.

- It allows for Variable Data Printing (digital printing customization). This allows the information from a database or external file, text and graphics to be changed on each printed piece without stopping or slowing down the press. For example, personalized letters can be printed with a different name and address on each letter. Variable data printing is used primarily for direct marketing, customer relationship development, and advertising.

- Great for “Sequential Numbering Printing”, which allows you to print items like raffle tickets, for example, where you need a unique identifying number printed in sequential order.

Things to Consider Before Choosing

- Customization: Digital printing offers the most affordable way to customize marketing materials, direct mail pieces, letters, etc.

- Quantity: Offset printing is the best for high-quantity runs! Short runs may have a high unit cost. But as quantities increase, the unit cost goes down with offset printing. Very short runs can be much more cost-effective with digital printing; while larger quantities are likely to have a lower unit cost with offset printing.

- Printing medium. If you need or want a special paper, finish, unusual printing surface, or a unique size, then offset printing still offers the most flexibility than digital printing. Offset presses accommodate larger printed pieces, like posters or plan drawings. On the other hand, digitally printed pieces have size and paper stock constraints.

- Turnaround Time: Digital printing is much faster than offset, so if you need something done quickly, then digital printing would be the way to go.

- Color: If you need only black ink or one or two ink colors, offset printing may offer a more cost-effective solution. If you need four-color printing, digital may offer lower costs, however, If you are planning on using the Pantone Matching System, offset printing will give you the best color match! With digital printing, the color that appears on the screen will be different from the color that is printed, but it is possible to get close to the desired colors.

- Proofing: Digital offers accurate proofs since you see an actual sample of the printed piece whereas offset proofs can be rather expensive when accurate colors are desired.

Truth Is… They Are BOTH Great!

The truth of the matter is, both digital and offset printing are great. Try not to stress in making a decision between the two. However, we are always more than happy to help you choose as well as to show you different samples of each so you can get a better idea of what your project will look like! Our awesome team works really hard to make sure that you are beyond satisfied with the results of your order. Feel free to contact us and pick our brains.